Why is Proper Sealing Necessary for Polystyrene Cladding?

Polystyrene cladding has become a popular choice for homes and commercial properties in Australia due to its excellent insulation and affordability. However, understanding seal polystyrene cladding is essential to maintaining its durability and performance is key. If you’ve installed or are planning to install polystyrene cladding, it’s important to recognise how sealing it correctly can protect your investment and extend the lifespan of your exterior. This article explores the importance of sealing, how it works, and when to apply it to keep your cladding in top condition.

What is polystyrene cladding?

Polystyrene cladding is a lightweight, durable material primarily used for its insulation properties. Made from expanded polystyrene (EPS), it helps maintain indoor temperatures by acting as an effective barrier against heat loss or gain. Key features include:

- Thermal insulation: Provides excellent insulation, reducing the need for excessive heating and cooling, leading to energy savings.

- Weather resistance: Resistant to the elements, making it suitable for various climates, including extreme heat or heavy rainfall.

- Cost-effective: Affordable and easy to install compared to other materials.

- Aesthetic flexibility: It can be finished in various styles for a modern or traditional look. Polystyrene cladding is an energy-efficient, cost-effective, and weather-resistant choice for residential and commercial use.

How weather affects the Sealing of Polystyrene Cladding?

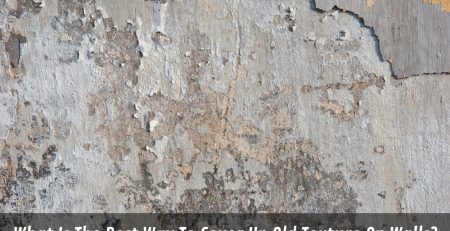

Weather conditions, including temperature, humidity, and rain, can impact the effectiveness of polystyrene cladding seals. Fluctuations in temperature may cause expansion or contraction, while moisture can weaken adhesives or cause water ingress. Extreme heat or cold can also lead to cracking or detachment of the sealant, affecting the cladding’s durability.

| Weather Condition | Impact on Sealing |

| Temperature Fluctuations | Causes expansion and contraction, potentially compromising the seal. |

| High Humidity | It can weaken adhesives, leading to a less effective seal. |

| Rain | Introduces moisture, which may cause water ingress or sealant degradation. |

| Extreme Heat | It may cause sealant to crack or detach, reducing durability. |

| Extreme Cold | It can make the sealant less flexible, leading to cracking or detachment. |

Why is proper sealing important for polystyrene cladding?

Proper sealing is essential to maximise the lifespan and performance of polystyrene cladding, protecting it from issues that impact its appearance, insulation, and structural integrity. By following the comprehensive wall cladding installation and maintenance guidelines provided by the National Construction Code (NCC), you can ensure the sealing process is carried out effectively.

- Moisture protection: Unsealed cladding is susceptible to water infiltration, which can cause the material to swell, degrade, and potentially lead to structural damage.

- UV protection: Without sealing, UV rays can break down the polystyrene material, leading to fading, brittleness, and loss of insulation value.

- Preserving appearance: Proper sealing protects your polystyrene cladding from dirt, grime, and weather damage, helping maintain its appearance.

- Enhancing durability: Sealed polystyrene cladding has an added layer of protection against impacts, scratches, and general physical damage.

When should you seal polystyrene cladding?

Sealing should be carried out at key stages throughout the lifespan of your cladding to ensure long-lasting protection. Here’s why seal polystyrene cladding is important and when you should seal it:

- Before installation: It’s crucial to apply a base coat or primer to the surface before installation. This enhances the cladding’s adhesion and provides a solid foundation for the sealant to bond effectively.

- Immediately after installation: Once the cladding is in place, apply a high-quality sealant to secure moisture resistance and protect against external elements, such as rain and UV rays.

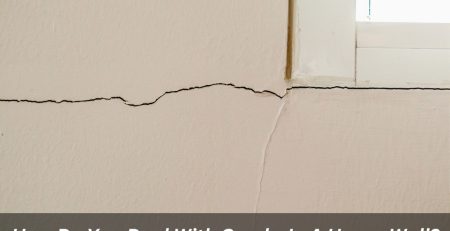

- Post-repair: If your cladding requires repairs, ensure the affected areas are resealed once the work is finished. This preserves the protective barrier and prevents further damage. Learn how to repair hairline cracks effectively to maintain the integrity of your cladding.

Proper sealing ensures optimal protection for your cladding. Consider professional sealing services in Sydney for the best results.

How often should you check the seals on your cladding?

Regularly checking the seals on your polystyrene cladding ensures it remains protected over time. Here’s how often you should inspect and maintain the seals:

- Annual inspections: At least once a year, inspect your cladding for any cracks or peeling in the sealant. This will help you catch any issues before they lead to more significant damage.

- After severe weather: Check the seals for signs of water infiltration or damage after storms or periods of heavy rain. Severe weather can sometimes cause the sealant to wear out.

- Reapplication: If the sealant has cracked or worn off, reapplying it will help protect your cladding, prevent cracks from developing, and contribute to sealing and fixing potential cladding cracks in rendered walls.

Why is sealing important for preventing mould growth?

Protecting your polystyrene is crucial to prevent moisture buildup and mould growth. Unprotected areas can easily absorb moisture, leading to damage. Here’s why seal polystyrene cladding is essential for prevention:

- Moisture resistance: A proper seal prevents water from seeping into the cladding, reducing the chances of moisture buildup that encourages mould growth.

- Health and hygiene: Mould can be a health hazard, particularly in high-humidity environments. Sealing your cladding ensures a clean, dry surface and prevents mould formation.

- Preserving aesthetics: Mould can damage the appearance of your cladding, leaving unsightly stains and affecting the overall aesthetic. Sealing helps to maintain the clean, fresh look of your exterior.

Is there a best type of sealant for polystyrene cladding?

When choosing a sealant for polystyrene cladding, selecting the right type to maximise its protective qualities is essential. Sealing plays an important role in ensuring long-lasting cladding protection. Here are the best sealant options for polystyrene cladding:

- Acrylic sealants: These are flexible, durable, and UV-resistant, offering excellent moisture protection while giving your cladding a smooth, clean finish.

- Silicone sealants: Known for their waterproof properties, they are perfect for areas with heavy rainfall and help keep your cladding free from mould and mildew.

- Polyurethane sealants: Ideal for high-traffic areas, these sealants are tough, long-lasting, and can easily handle harsh weather conditions.

Acrylic, silicone, and polyurethane sealants are all excellent choices for sealing polystyrene cladding. Each offers specific advantages based on your needs.

Conclusion

Sealing your polystyrene cladding is vital for protecting your investment and ensuring its long-term performance. A high-quality sealant is a barrier against moisture, UV damage, physical wear, and mould growth, helping maintain the cladding’s appearance and insulating efficiency. Regular inspections and timely reapplication of sealant will preserve its integrity, ensuring that your cladding continues to perform at its best for years to come.

Looking to improve your home’s exterior? Explore how Jims Rendering Sydney can help you with quality rendering solutions.