What Are The Common Errors In Installing Polystyrene Cladding?

What are the most common mistakes in installing polystyrene cladding?

While polystyrene cladding can enhance the appearance and energy efficiency of your building, it is essential to get the application right to avoid potential polystyrene cladding problems. Some of the most common mistakes include:

- Incorrect surface preparation: Please clean and prepare the surface before cladding to avoid adhesion problems.

- Improper adhesive use: Using the wrong adhesive or insufficient amounts can lead to cladding detaching or not sticking properly.

- Incorrect fastening: Failing to secure the cladding properly can result in it shifting or falling off.

- Incompatible render materials: Using incompatible materials can affect the durability and appearance of the cladding.

- Failure to account for expansion gaps: Not leaving space for the cladding to expand and contract can lead to cracking.

How can poor surface preparation affect polystyrene cladding installation?

Surface preparation is critical to the success of polystyrene cladding applications. If the surface is adequately cleaned and prepared, the cladding may adhere properly, leading to an uneven finish or detachment over time.

- Dirt and debris: Dust, dirt, and grime can prevent the adhesive from bonding to the wall, resulting in weak adhesion.

- Surface irregularities: If the wall surface is not smooth, the cladding may not fit correctly, creating gaps or making it unstable.

- Moisture: Any moisture on the surface can affect adhesion and lead to mould or mildew growth, compromising the integrity of the cladding.

Why is proper adhesion necessary for polystyrene cladding?

The adhesive is the foundation for securing polystyrene cladding to your wall. If the adhesive is not applied correctly, the cladding will not adhere properly, leading to a host of polystyrene cladding problems.

- Even distribution: The adhesive must be evenly spread across the surface to ensure consistent bonding.

- Right adhesive type: Using an adhesive that is not suited for polystyrene cladding can result in premature failure or detachment.

- Sufficient adhesive quantity: Not using enough adhesive can leave parts of the cladding unsupported, causing it to shift or fall off over time.

- Temperature considerations: Applying adhesive in inappropriate weather conditions, such as extremely cold or hot temperatures, can affect its performance.

What are the risks of incorrect insulation installation with polystyrene cladding?

Polystyrene is chosen for its insulation properties, but incorrect applications can diminish its effectiveness.

- Gaps in insulation: If there are gaps between the cladding panels, it will compromise the thermal performance, leading to heat loss or poor temperature regulation.

- Inconsistent coverage: Insulation needs to be applied uniformly to ensure that the building maintains a consistent temperature.

- Incorrect material thickness: Using the right thickness of polystyrene can lead to adequate insulation, which can affect both comfort and energy efficiency.

To maximise the benefits of polystyrene cladding, the insulation must be installed correctly and fully cover the area.

What are the consequences of using incompatible render materials with polystyrene cladding?

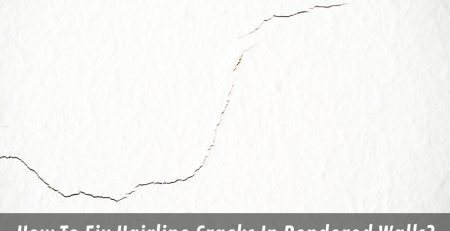

Rendering enhances the finish of polystyrene cladding, but using incompatible render materials can lead to polystyrene cladding problems, such as cracking or detachment.

- Cracking and peeling: Certain types of render may not bond well with polystyrene, leading to cracks or peeling over time.

- Water infiltration: Some renders may not provide the water resistance necessary to protect the cladding and wall beneath it, leading to moisture penetration.

- Discolouration: Incompatible render materials may not adhere to the cladding evenly, resulting in uneven colours or texture.

- Reduced durability: The wrong render can reduce the lifespan of the cladding, leaving it vulnerable to weather damage.

How can weather conditions impact the quality of polystyrene cladding installation?

The weather conditions during installation play a significant role in the final result. Extreme temperatures due to Australia’s warming climate, humidity, and rainfall can all negatively impact the installation process.

- Hot weather: High temperatures can cause the adhesive to dry too quickly, leading to poor bonding. It can also cause the cladding to expand or warp.

- Cold weather: Cold conditions can slow down the curing process of the adhesive, leading to weak bonds.

- Rain: Rain can wash away adhesives or prevent the surface from drying correctly, affecting adhesion.

For best results, install polystyrene cladding in mild, dry weather, taking precautions in adverse conditions.

Why is it essential to follow local building codes when applying cladding?

Sydney has specific building codes and regulations that must be adhered to when installing the best cladding for your home. These regulations ensure the safety, durability, and structural integrity of your building.

- Fire safety: Certain areas may require fire-resistant cladding, and not following these guidelines can put your property at risk.

- Structural integrity: Building codes ensure that the cladding is installed in a way that will not compromise the structure of your home.

- Compliance with local standards: By following the relevant codes, you ensure that your property meets local legal requirements, avoiding costly fines or the need for rework.

Why Is professional installation crucial for polystyrene cladding?

Professional installation is key to ensuring polystyrene cladding is done correctly. Here’s why:

- Precision and Quality: Trained professionals ensure accurate, secure, and long-lasting installation.

- Avoiding Costly Mistakes: They prevent common issues that could lead to expensive repairs.

- Safety: Professionals handle materials safely, minimising risks.

- Compliance with Building Codes: They ensure the installation meets local regulations.

- Efficient Installation: Professional polystyrene cladding installation services complete the job quickly and to the highest standard.

Conclusion

Ensure a proper installation for long-lasting results

At Jim’s Rendering Sydney, we pride ourselves on attention to detail and delivering your design vision within budget. Our qualified team specialises in residential and commercial polystyrene cladding installation using high-quality, durable materials. With a solid warranty and local expertise, we ensure your project complies with all Sydney building codes. Trust Jim’s Rendering for professional, reliable service. Contact Jim’s Rendering today!